SPECIAL COATING SYSTEMS

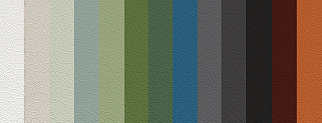

Marcegaglia’s experience and know-how in the pre-painted steel flat products has led to the development of special coating systems, developed to ensure better resistance to UV rays and corrosion, guaranteeing excellent flexibility and durability, which find application in the construction sector.

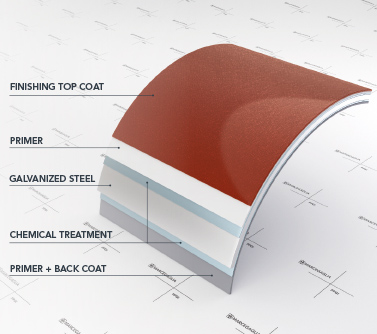

Marcegaglia SHIMOCO® coating system is formulated to provide the best UV and corrosion resistance, guaranteeing maximum flexibility and durability, as well as having a pleasant and elegant appearance thanks to the paint’s uniform and textured composition.

SHIMOCO® polyester coating system is free of hexavalent chromium and heavy metals. Developed primarly for roofing applications, it is also suitable for cladding and façades.

SUBSTRATE: galvanized Z275

ANTI-CORROSION PRIMER: polyurethane

BACK COAT: epoxy-polyester

A – Primer + Top: 30+30 µm

B – Back: 12 µm

Specular gloss (EN 13523-2): 5-15

Adhesion after bending (EN 13523-7): 1.0 T

Flexibility after bending (EN 13523-7): 1.5 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 750

Corrosion class (EN 12944-2): RC5

Condensed water constant atmosph. (EN 13523-25): 2000

UV resistance (EN 10169): RUV 4

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.5 kg

Fire classification (EN 13501-1): NA

Warranty: 30 years

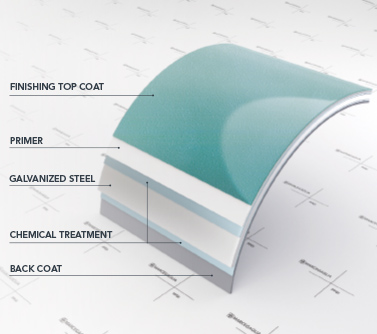

Marcegaglia PLASTISOL is formulated accordingly to two different coating systems to allow two separate painting cycles: MPS100 and MPS200.

The only PVC coating system suitable for interior and exterior applications with a 30 year warranty on products.

MPS100

Suitable for façades and insulated panels for indoor applications

MPS200

Suitable for walls, roofs and insulated panels for outdoor applications (particularly aggressive environments, in terms of pollution and industrial areas)

SUBSTRATE: galvanized Z275

ANTI-CORROSION PRIMER: acrylic primer

BACK COAT: epoxy

A – Primer + Top: 7+200 µm

B – Back: 12 µm

Specular gloss (EN 13523-2): 30

Adhesion after bending (EN 13523-7): 0.5 T

Flexibility after bending (EN 13523-7): 1.0 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): NA

Salt spray resistance (EN 13523-8): 1000

Corrosion class (EN 12944-2): RC5

Condensed water constant atmosph. (EN 13523-25): 2000

UV resistance (EN 10169): RUV 4

Resistance to solvent (EN 13523-11): NA

Scratch resistance (EN 13523-12): NA

Fire classification (EN 13501-1): C-S2-D0

Warranty: 30 years

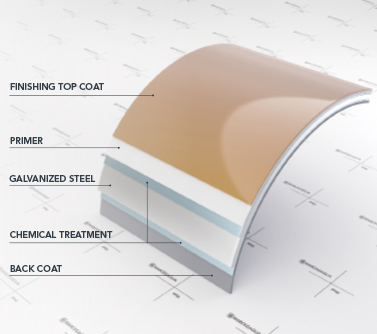

The “MPROOF system” name identifies a prepainted steel with high scratch resistance and superlative uv stability; the paint cycle is a combination of high thickness primer and a polyurethane top coat added with ceramic and acrylic beads that guarantee a high degree of resistance to the external aggression.

This finished product was primarily developed for roofing and cladding installed at high altitude, where irradiation and thermal shock could be severe;

SUBSTRATE: galvanized Z275

ANTI-CORROSION PRIMER: epoxy-polyester primer

BACK COAT: epoxy-polyester

A – Primer + Top: 5+20 µm

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 10-15

Adhesion after bending (EN 13523-7): 1.0 T

Flexibility after bending (EN 13523-7): 1.5 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 500

Corrosion class (EN 12944-2): RC3

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): RUV 4

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.5 kg

Fire classification (EN 13501-1): NA

Warranty: 15 years