PATTERN COATING SYSTEMS

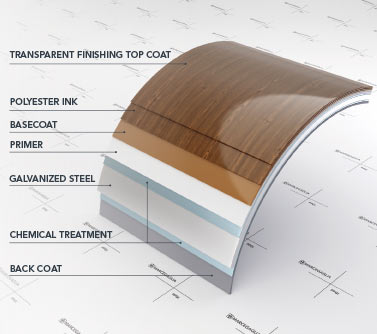

Coating systems suitable for indoor and outdoor applications and have the peculiarity of simulating the surface aesthetic value of special textures and finishes such as wood, ardesia, and tile, printed directly on steel.

Unique painting system which simulates the surface appearance of wood, but painted directly onto steel, formulated for interior (MPWI) and exterior (MPWOS and MPWOR) applications with excellent resistance to corrosion and UV rays, guaranteeing maximum durability.

Supplied in four different colors (maple, golden oak, dark oak, black walnut) with four different surfaces (smooth, polyamide, wrinkled and wrinkled 3D deconstructed), it is free of toxic pigments, such as chromate, molybdate and lead salts pigments and presents specific features in painting cycle depending on its installation.

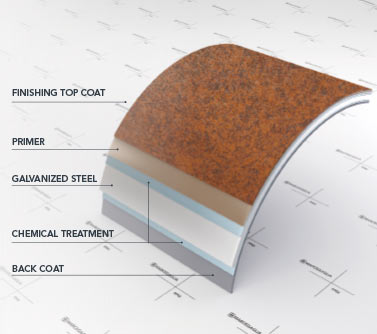

SUBSTRATE: galvanized Z140-Z225

ANTI-CORROSION PRIMER: epoxy-polyester primer

BACK COAT: epoxy-polyester

A – Primer + Top: 30 µm (35 µm *)

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 20-30 (0-30 MPWOS)

Adhesion after bending (EN 13523-7): 1.5 T (0.5 T *)

Flexibility after bending (EN 13523-7): 2.5 T (1.0 T *)

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): NA (500 *)

Corrosion class (EN 12944-2): NA (RC4 *)

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): NA (RUV 4 *)

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.2 kg

Fire classification (EN 13501-1): A1

Warranty: NA (15 years *)

(*) for MPWOS – MPWOR

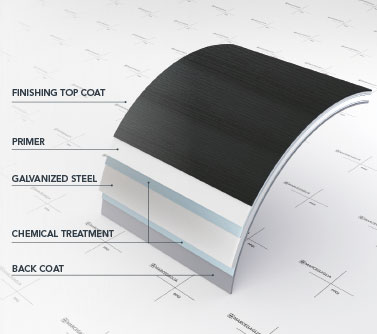

The name ARDESIA identifies a polyester-painted steel with a wrinkled surface. It is specifically designed for roofs with a “false tile” appearance or in any case with 0 gloss properties; the prepainted product can be compared to the Marcegaglia MP4 system, with a predicted average life of at least 10 years.

Developed primarily for roofing applications, it is also suitable for walls and sectional doors.

SUBSTRATE:

MPSTONE galvanized Z140

MPSTONE AS galvanized Z225

MPSTONE20 galvanized Z275

A – Primer + Top: 5+20 µm

(15+20 µm MPSTONE AS / 25+20 µm MPSTONE 20)

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 6-60

Adhesion after bending (EN 13523-7): 1.0 T

Flexibility after bending (EN 13523-7): 2.0 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 500

Corrosion class (EN 12944-2): RC3 (Z225)

(RC4 MPSTONE AS and MPSTONE 20)

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): RUV 3

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.0 kg

Fire classification (EN 13501-1): A1

Warranty: 10 years

(15 years MPSTONE AS / 20 years MPSTONE 20)

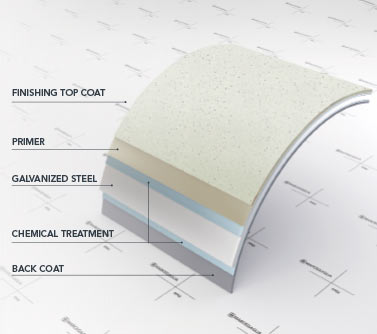

Marcegaglia-quality pre-painted steel with polyester resins that guarantees a very versatile finished product: the new COPPO coating system.

The design is created by the ink stains in order to simulate the aging that the traditional corp undergoes over time as faithfully as possible and is subject to variations in color and coverage.

Especially suitable for applications on residential roofs in normal environments with an average pollution rate, with an estimated life of at least 10 years.

SUBSTRATE: galvanized Z140

ANTI-CORROSION PRIMER: epoxy-polyester primer

BACK COAT: epoxy-polyester

A – Primer + Top: 5+20 µm

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 15-20

Adhesion after bending (EN 13523-7): 1.5 T

Flexibility after bending (EN 13523-7): 2.5 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 500

Corrosion class (EN 12944-2): RC3 (Z225)

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): RUV 2

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.0 kg

Fire classification (EN 13501-1): A1

Warranty: 10 years

The name “MPWALL system” identifies a pre-painted steel decoratedwith a faux wall effect; the painting system’s pronounced visual impact has been designed to compensate for the limitations of steel covered with laminated plastic.

The aliphatic transparent finish guarantees significant resistance for exterior use, with an approximate duration of at least 15 years (provided both parties have reached an agreement and in presence of our evaluation of the installation site).

SUBSTRATE: galvanized Z225

ANTI-CORROSION PRIMER: epoxy-polyester primer

BACK COAT: epoxy-polyester

A – Primer + Top: 35 µm

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 5-10

Adhesion after bending (EN 13523-7): 0.5 T

Flexibility after bending (EN 13523-7): 1.0 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 500

Corrosion class (EN 12944-2): RC4

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): RUV 4

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.2 kg

Fire classification (EN 13501-1): A1

Warranty: 15 years

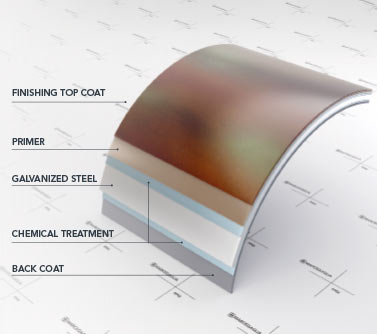

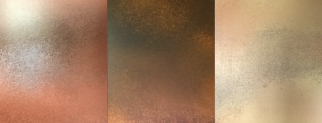

The name “MPCORTEN” identifies a corten surface reproduction in prepainted steel; the final product’s impressive visual impact guarantees an average predicted life of at least 15 years (provided both Parties have reached an agreement and subject to our evaluation of the installation site).

SUBSTRATE: galvanized Z225

ANTI-CORROSION PRIMER: epoxy-polyester primer

BACK COAT: epoxy-polyester

A – Primer + Top: 35 µm

B – Back: 5/7 µm

Specular gloss (EN 13523-2): 5-15

Adhesion after bending (EN 13523-7): 0.5 T

Flexibility after bending (EN 13523-7): 1.0 T

Adhesion after indentation (EN 13523-6): 9

Pencil hardness (EN 13523-4): F

Salt spray resistance (EN 13523-8): 500

Corrosion class (EN 12944-2): RC4

Condensed water constant atmosph. (EN 13523-25): 1000

UV resistance (EN 10169): RUV 4

Resistance to solvent (EN 13523-11): min. 100 dc MEK

Scratch resistance (EN 13523-12): >2.2 kg

Fire classification (EN 13501-1): A1

Warranty: 15 years